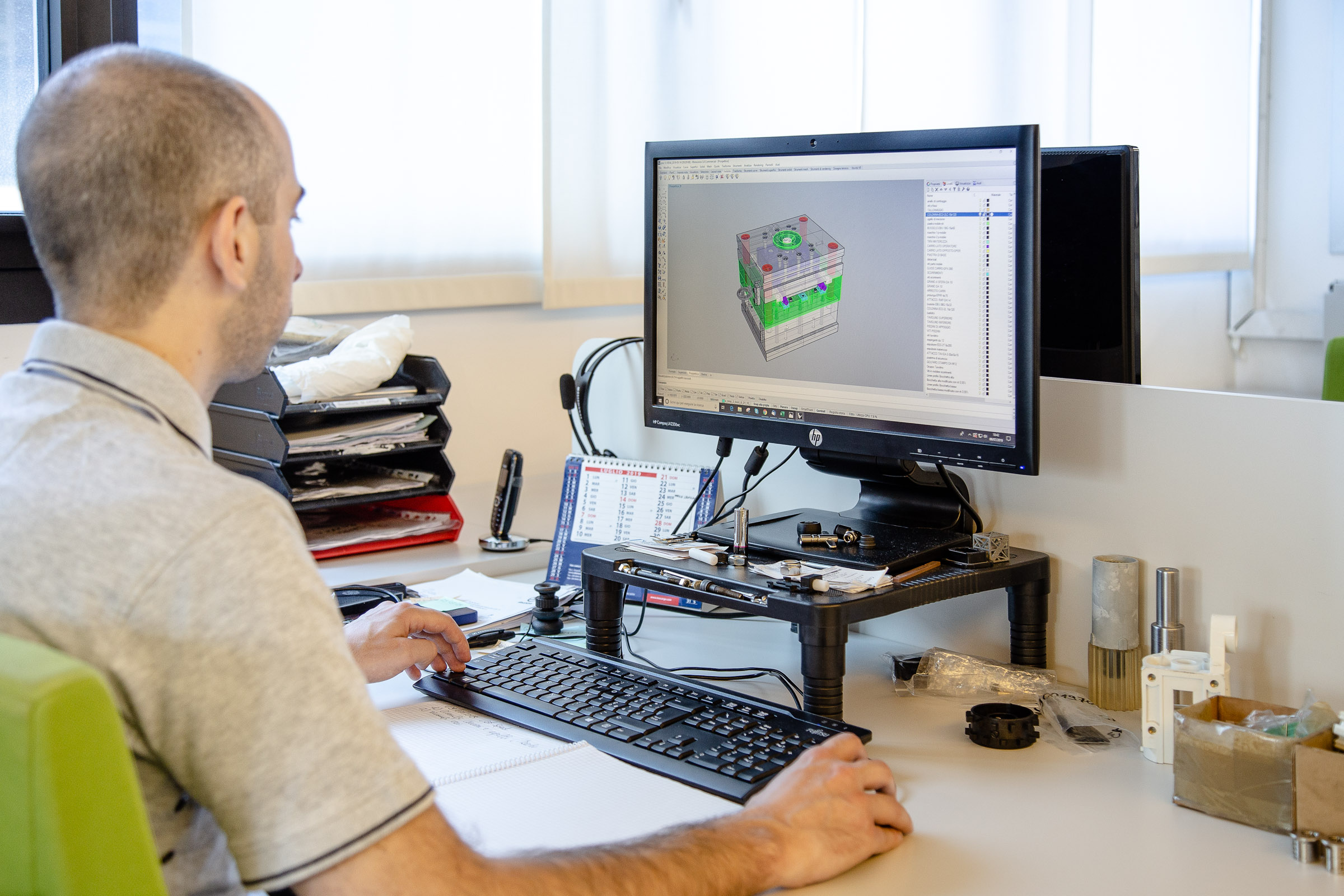

Injection moulding is still the prominent manufacturing process involving polymer based parts. This process allows for a large production scale while still granting a high level of custom manipulation.

TECNOPLAST moulding machinery department houses 37 units and is able to work with all sorts of plastic polymer based materials. We’ve invested in electric injection moulding machines that grant maximum precision and consistency within all phases of the moulding process.

TECNOPLAST also acts as a subcontractor (once provided with the design by the client) for parts needed in specific mechanical and electrotechnical applications. A few of our services:

- Replacement of structural metal parts with high performance polymers (metal replacement).

- Production of self-lubricating mechanical components with low coefficient of friction and high wear resistance, thanks to a sound analysis of their tribological properties.

- Printing over existing metal components.

- Production of mechanical components with large thickness.

Our products’ properties

Structural properties:

- High rigidity

- High load capacity

- Shock resistance

- Dimensional Stability

- Thermal stress

- Chemical resistance

- Antistatic & Conductive

- Flame resistance

Tribological properties:

- Wear resistance

- Low coefficient of friction

- Abrasion resistance

- Low noise output

- Stick-slip behaviour

- Wear resistance

- Low coefficient of friction

- Abrasion resistance

- Low noise output

- Stick-slip behaviour